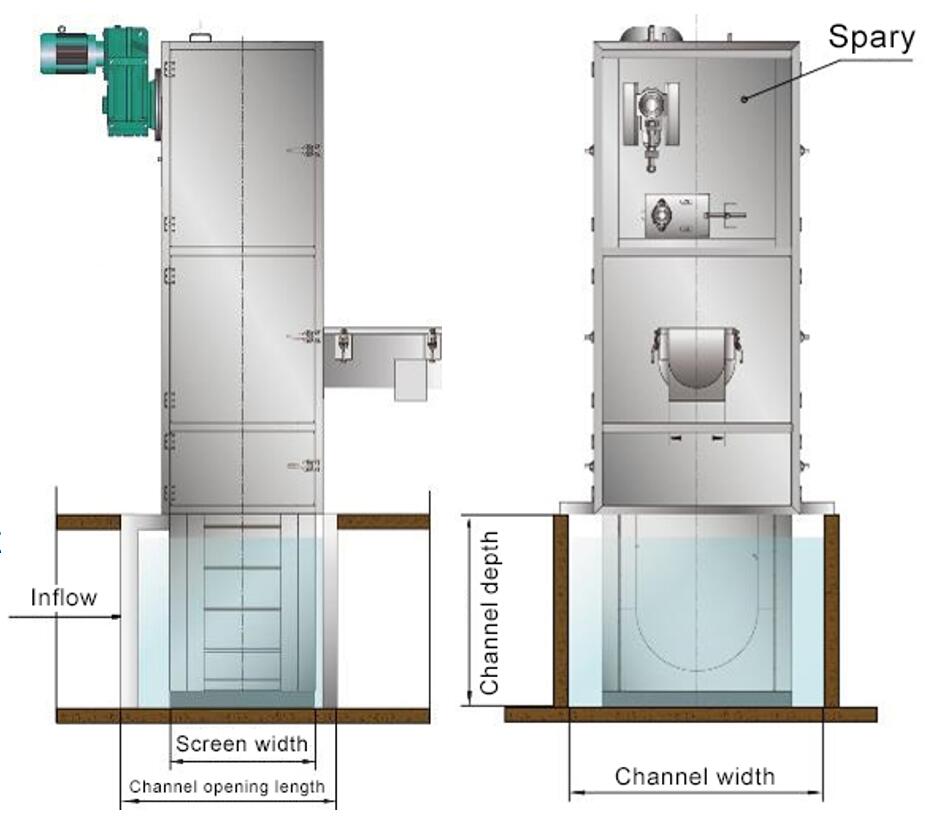

The Inner Flow Grille is composed of six parts: frame, drive system, grid system, backwash system, slag removal system and electric control system. The gear motor drives the sprocket to rotate, and the sprocket drives the net board to rotate continuously; The sewage enters the grille from the water inlet and is filtered by the mesh plate. After filtration, the water flows to the outside of the net board, and the dirt is trapped on the inner surface of the net board, and it is brought to the top with the continuous rotation of the net board. The backwashing system flushes the outside of the net board, and the dirt is washed to the slag collection tank under the action of the flushing water, and flows out of the sewage outlet with the flushing water.

The rotating panels are positioned parallel to the flow and as wastewater enters the screen it flows through the perforated screening panels. Easy to retrofit into existing channels and installs at a 90° inclination.

Unique Flow Design

+ Zero carryover and the highest capture rate of all screens*.

+ Perforated openings capture twice as much debris as bar screens.

+ Perforated UHMW inserts limit hair pinning (replaceable) with stainless steel frame.

Enhanced Cleaning System

+ Spray bar keeps the screen’s panels clear.

+ Stainless steel construction ensures long life.

+ Roller chains track smoothly in UHMW guides.

Equipment Sizing

Screen panel hole size: 1,2,3,4,5 or 6mm

Perforations

Minimum Wash Water Head at Spray Jets: 55 PSI (3.8 bar)

Materials of Construction

Screen Structure: 304 or 316 Stainless Steel

Screen Panels:UHMW Plates,1/4” or 3/8‘’ Thick

Application

Urban sewage, municipal sewage pipe channels.

Separation of debris at water intakes such as water works and power plant cooling water.

It can also be used for washing or pretreatment screening in the production process of textile, fruit, aquatic products, paper making, wine making, slaughtering, tanning and other industries.