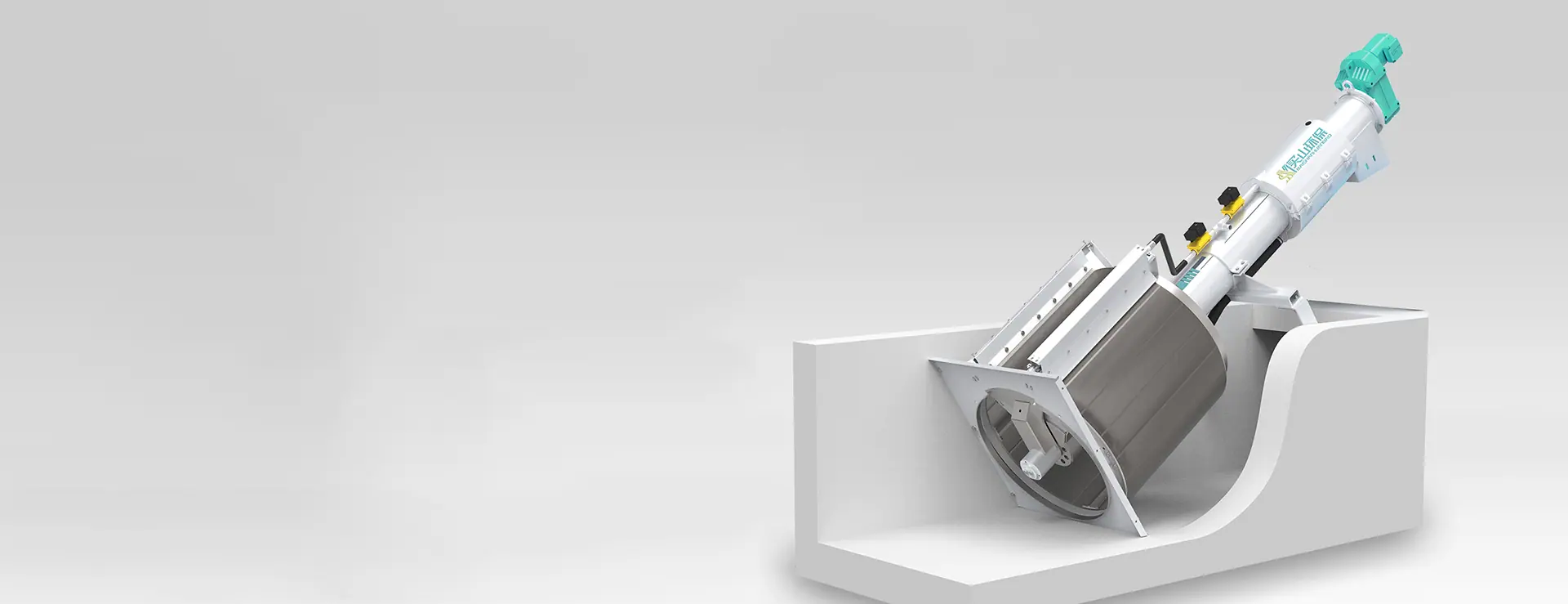

The rotary drum fine screen consists of a rotary drum assembly, a screw shaft, conveying and pressing pipes, a stand, a rinsing device, and an electrical cabinet.The screen mesh of the rotary drum fine screen is self-cleaning during operation. The equipment runs slowly, debris and hard objects will not damage the equipment, the screen will not clog, and there are nylon brushes inside the screen. The fine screen has filtering, pressing, dewatering and conveying functions. Fully sealed structure prevents odour leakage. Stable operation of the equipment, low energy consumption, low noise, small gap between the grids, separation efficiency can be more than 97% through fluid diversion.

The rotary drum fine screen consists of a rotary drum assembly, a screw shaft, conveying and pressing pipes, a stand, a rinsing device, and an electrical cabinet.The screen mesh of the rotary drum fine screen is self-cleaning during operation. The equipment runs slowly, debris and hard objects will not damage the equipment, the screen will not clog, and there are nylon brushes inside the screen. The fine screen has filtering, pressing, dewatering and conveying functions. Fully sealed structure prevents odour leakage. Stable operation of the equipment, low energy consumption, low noise, small gap between the grids, separation efficiency can be more than 97% through fluid diversion.

The rotary drum fine screen consists of a rotary drum assembly, a screw shaft, conveying and pressing pipes, a stand, a rinsing device, and an electrical cabinet.The screen mesh of the rotary drum fine screen is self-cleaning during operation. The equipment runs slowly, debris and hard objects will not damage the equipment, the screen will not clog, and there are nylon brushes inside the screen. The fine screen has filtering, pressing, dewatering and conveying functions. Fully sealed structure prevents odour leakage. Stable operation of the equipment, low energy consumption, low noise, small gap between the grids, separation efficiency can be more than 97% through fluid diversion.

The shaft screw conveyor press of rotary drum screen can effectively press and dewater the grizzly slag. During the transport process, the water in the grated slag will flow out due to gravity.

The underwater bearing adopts copper alloy sliding bearing, which has the advantages of water-resistant, corrosion-resistant, wear-resistant, etc. It can slide in the water by itself without adding lubricating oil, which can ensure the long-term operation of the equipment without maintenance and extend the service life of the equipment. No maintenance is required, which prolongs the service life of the drum screen.

The rotary drum screen has a grid frame flushing system, and the flushing flow is controlled by a solenoid valve.

The Rotary Drum Screen has four functions: sludge interception, sludge removal, screw lifting and press dewatering. The drum is installed in a channel at an angle of 35 degrees. Wastewater flows into the drum through the drum ports, where a grille intercepts the sludge. The drum then rotates at a fixed speed, with nylon brushes and rinse water jets above the drum removing the sludge and exporting it via screw jacking. After dewatering and pressing, the dregs are conveyed to containers or transport equipment. The whole process is clear and odourless.