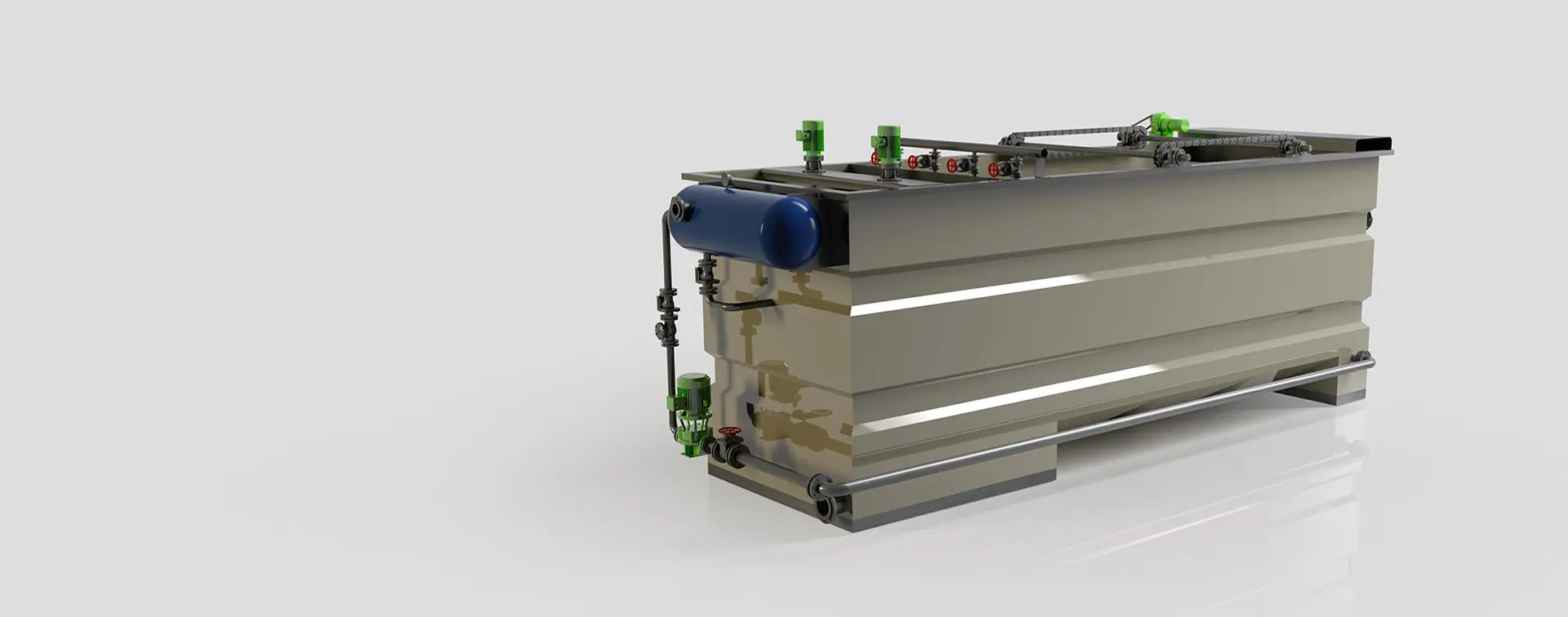

Dissolved Air Flotation (DAF) system consists of a highly efficient air dissolution system.

Dissolved Air Flotation (DAF) equipment is effective in wastewater, industrial wastewater, oily sewage separation, activated sludge thickening, clarified water recycling. It can also be used as a clarification and purification system in other application.

During the process of air flotation, a large number of fine and uniform bubbles (5~80μm) are formed, the smaller the bubbles are, the easier and denser the attachment of suspended solids to the bubbles is. Air bubbles as a carrier, and the suspended floc particles in the water fully mixed, attached, so as to form a three-phase mixture of air bubbles, water, floc (oil). The floc wrapped with air floats up to the surface of the liquid, and the scum is skimmed off through the scum scraping machine (glass fibre reinforced plastic scraper), so as to achieve the purpose of separating impurities and purifying water quality.

The theoretical basis of the dissolved air process comes from Henry’s Law. In the dissolved air flotation system, air is dissolved in water at high pressure and close to saturation, and is released at reduced pressure to atmospheric pressure, and the dissolved saturated air is precipitated out of the water in the form of tiny bubbles for flotation.

Due to the increased attachment capacity of the fine bubbles, the saturation of the introduced air as well as the reduction capacity of the particles increases the reduction capacity of the suspended solids, thus increasing the solids content in the flotation and making the flotation on the surface of the micro-aerofloat cell more stable.